Anchors Aweigh! 7 LiFePO4 Marine Battery Installation Pitfalls Every Boat Owner Must Avoid

For boat owners upgrading to marine lithium iron phosphate (LiFePO4) batteries, the switch promises longer lifespan, lighter weight, and reliable deep-cycle power. Yet improper installation can sink your investment faster than a cannonball. Powerurus reveals critical installation traps – and how to navigate them safely.

Pitfall 1: Ignoring Battery Management System (BMS) Compatibility

The Risk: Non-marine-rated BMS may fail to prevent thermal runaway in saltwater environments.

Powerurus Solution: Choose batteries with IP67 waterproof rating (like Powerurus 12V/24V series), or verify BMS integrates temperature cutoffs (-20°C to 65°C) and salt-spray resistance

Pitfall 2: Incorrect Voltage System Sizing

The Risk: Mismatched 12V/24V/36V systems throttle trolling motors or navigation electronics.

Smart Wiring: A 36V trolling motor needs three 12V batteries in series – single 36V units avoid imbalance issues.Powerurus 36V marine batteries eliminate series wiring failure points.

Pitfall 3: Overlooking Vibration Damage

The Reality: Wave impacts crack standard battery internals within months.

Installation Must:

Mount batteries with anti-vibration pads(NMEA 0400 compliant)

Use Powerurus’ internal cell-stabilization techwith 50G shock resistance

Pitfall 4: Charging With Lead-Acid Profiles

Battery Killer: Lead-acid chargers overvolt LiFePO4 cells, causing catastrophic failure.

Do This Instead:

Program chargers for LiFePO4 voltage curve (14.2–14.6V for 12V systems)

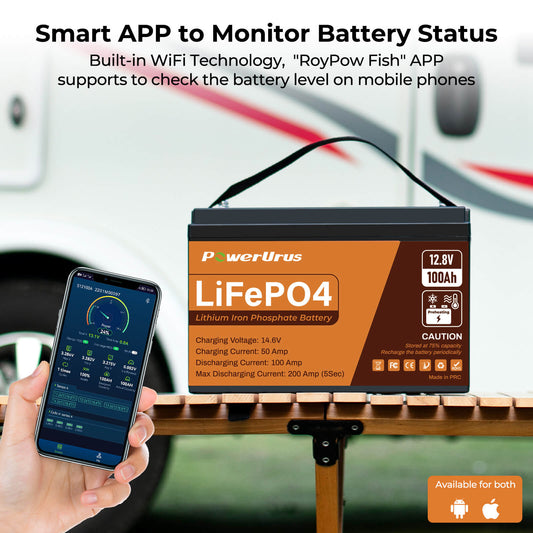

Use Powerurus’ multi-stage marine chargers with Bluetooth health monitoring

Pitfall 5: Inadequate Ventilation

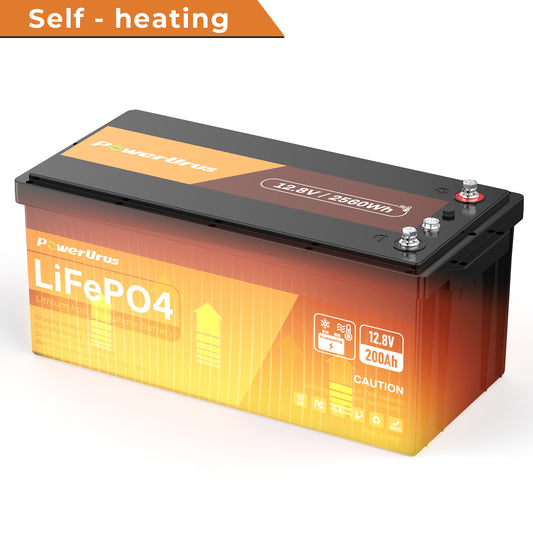

Thermal Danger: Tight compartments trap heat – LiFePO4 degradation accelerates above 45°C (113°F).

Best Practice:

Maintain 3+ inches clearance around batteries

Powerurus batteries feature passive cooling fins for confined bilges

Pitfall 6: Neglecting Electrical Leak Protection

Corrosion Hazard: Saltwater exposure causes terminal shorts in days.

Battle Corrosion:

Apply dielectric grease on terminals

Install batteries above waterline with drip-proof boxes

Powerurus’ marine-grade aluminum cases resist galvanic corrosion

Pitfall 7: Skipping Load Testing

Hidden Fault: Undetected voltage drops strand boats offshore.

Pre-Launch Checklist:

Test at peak trolling motor amps (e.g. 80A for 24V systems)

Verify < 3% voltage sag under load.

Powerurus batteries maintain >99% round-trip efficiency at max discharge.

Why US Boaters Choose Powerurus LiFePO4

1. 200+ Cycles Per Year – Lasts 3X longer than AGM in daily fishing use

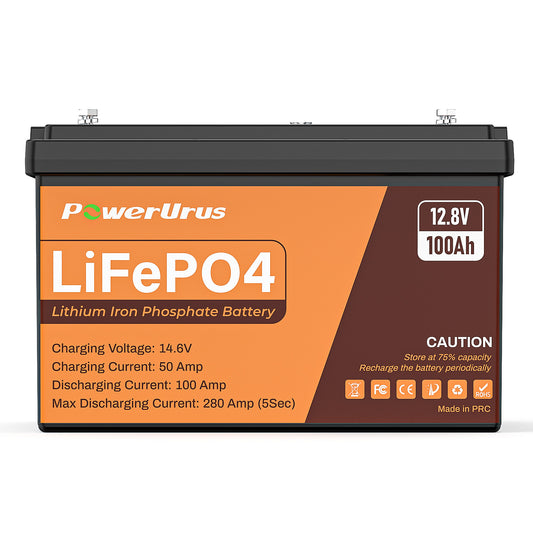

2.50% Weight Savings – Powerurus 100Ah 12V = 25 lbs vs. AGM’s 67 lbs

3.True Deep Discharge – Recover 100% capacity after 80% DoD (AGM degrades at 50%)

4.Zero Maintenance – No water refills for 10+ year lifespan

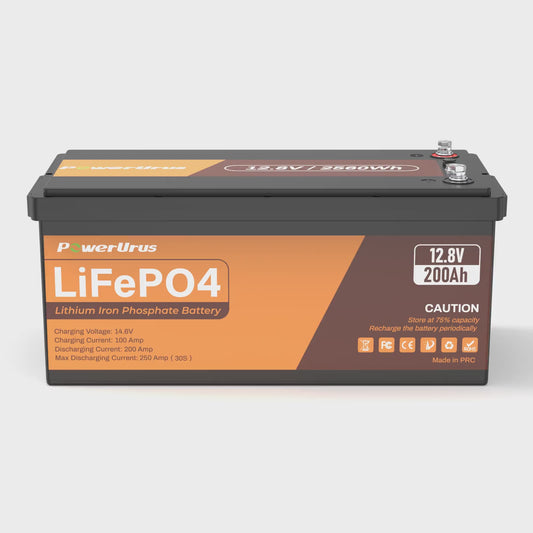

Case in Point: Florida charter captain replaced 8 AGMs with two stacked Powerurus 24V 200Ah batteries. Saved 428 lbs, gained 18% range, and 3 years later, still at 96% capacity.

Navigate Your Lithium Upgrade Confidently!

Explore Powerurus’ Saltwater-Read LiFePO4 Solutions.