Golf Cart Battery Winter Maintenance Guide: Protect Power in Freezing Temperatures

Winter poses unique challenges for golf cart batteries, from reduced capacity to freezing risks. Here’s how to safeguard your batteries during cold months, using strategies validated by industry experts and real-world case studies.

1. Electrolyte Antifreeze Measures

Lead-acid batteries are vulnerable to electrolyte freezing below -20°C, which can crack cases and damage plates. To prevent this:

Maintain full charge: A fully charged lead-acid battery freezes at -50°C vs. -10°C at 50% charge . Check specific gravity (1.28–1.30) to ensure proper charge density .

Use insulated blankets: Wrap batteries in thermal covers to retain heat during sub-zero nights .

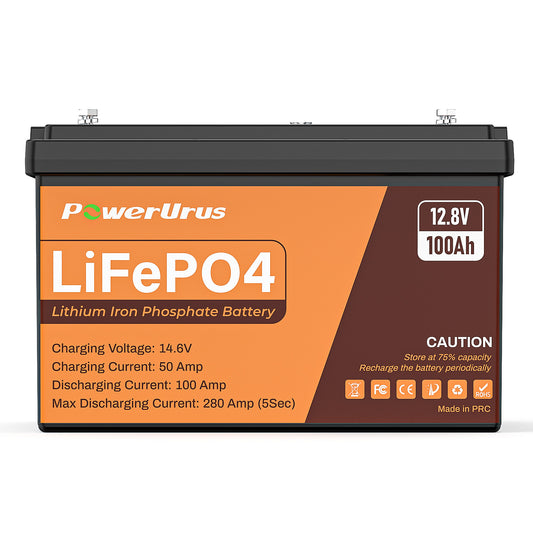

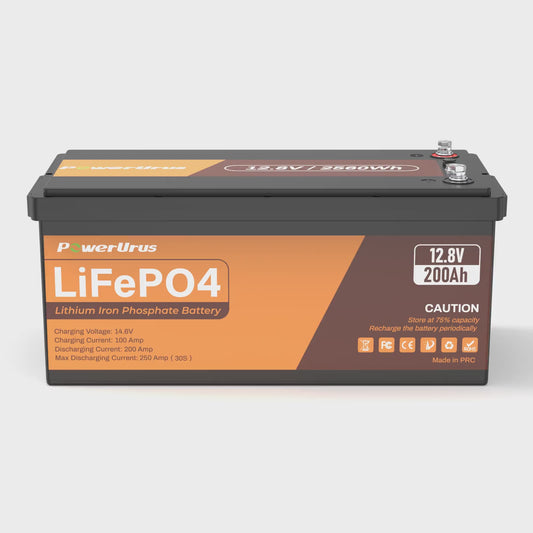

Switch to lithium or gel batteries: Lithium-ion (operational down to -30°C) and colloid batteries (e.g., EVGC6A-A) resist freezing due to stable electrolyte structures .

2. Charging Temperature Control

Charging in cold conditions requires precision:

Charge above 10°C: Charging lead-acid batteries below this threshold risks incomplete sulfation reversal. Use heated storage areas or battery warmers to maintain optimal temperatures .

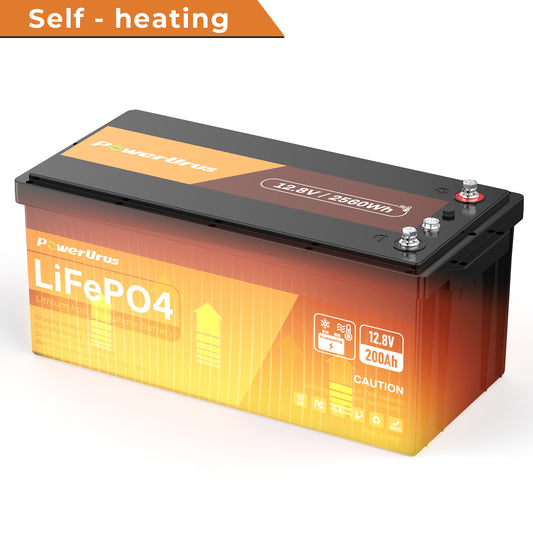

Preheat lithium batteries: Some lithium systems feature built-in preheating circuits to condition cells before charging in cold environments .

Avoid rapid charging: Limit charging rates to 0.2C (e.g., 20A for 100Ah batteries) to reduce heat generation and stress .

3. Combat Reduced Winter Capacity

Battery capacity drops 20–40% in freezing weather. Mitigate this with:

Preheating systems: Install battery warmers or install carts in climate-controlled storage. A Canadian golf course reduced winter downtime by 40% using thermal-regulated battery compartments .

Minimize deep discharges: Keep state of charge (SOC) above 50% to avoid voltage sag. Use lithium batteries with low-temperature discharge modes for consistent power .

Shorten usage intervals: Plan shorter routes and reduce loads (e.g., avoid towing) to lessen strain on cold batteries .

4. Winter Storage Best Practices

For carts unused during winter:

Disconnect terminals: Prevent parasitic drain, which accelerates capacity loss .

Store at 30–50% SOC: Ideal for lead-acid; lithium prefers 50–70% .

Monthly maintenance charges: Recharge every 4–6 weeks to counteract self-discharge .

Case Study: Avoiding Disaster

A Michigan resort avoided a $15,000 battery replacement cost by adopting colloid batteries (IP67-rated) and installing insulated storage. Despite -25°C temperatures, the batteries retained 85% capacity, outperforming traditional lead-acid units .

Final Tips

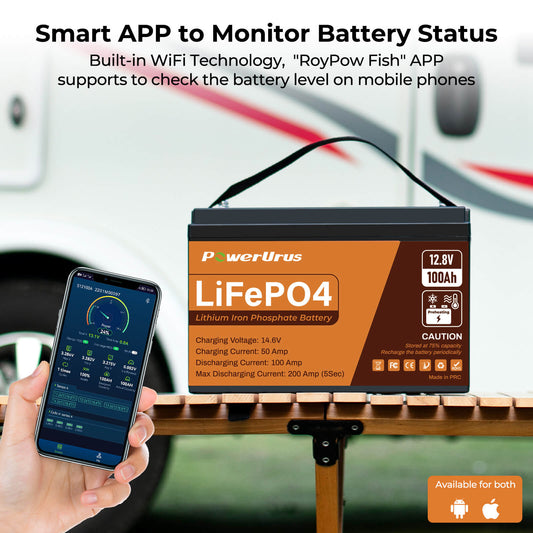

Upgrade to smart chargers: Use temperature-compensated chargers that adjust voltage based on ambient conditions .

Monitor voltage weekly: A 48V system should read 50.9V+ when fully charged; deviations signal issues .

By combining proactive maintenance, advanced battery tech, and temperature management, golf cart operators can ensure reliable winter performance.