Parallel vs. Series Wiring: Which Boosts 48V LiFePO4 Battery Bank Efficiency?

Choosing between parallel and series wiring for 48V LiFePO4 systems impacts cost, safety, and scalability. We break down the engineering trade-offs with real data.

When to Choose Series Wiring

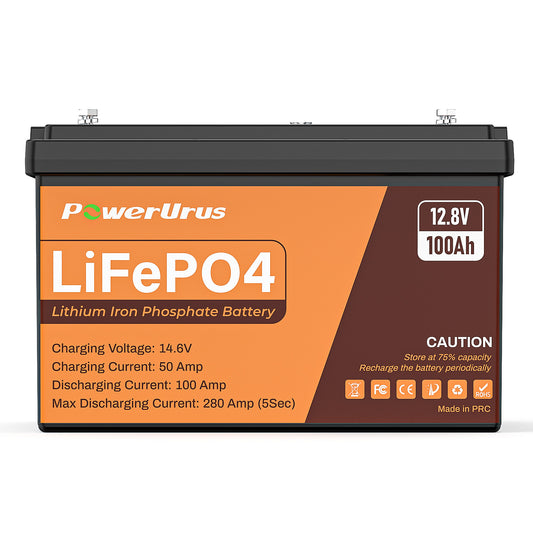

Scenario: Building a 48V system from 12V LiFePO4 batteries.

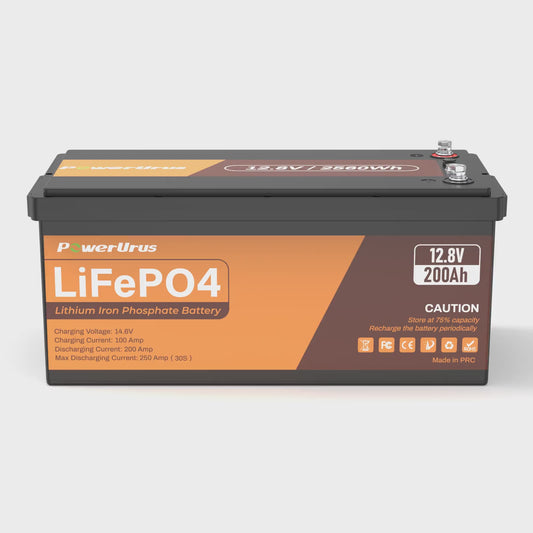

How It Works: Connect four 12V 200Ah LiFePO4 in series (12V×4 = 48V).

Advantages:

Lower Copper Costs: 48V systems use thinner cables. For a 100A load:

Series (48V): 6AWG ($2.50/ft)

Parallel (12V): 2/0 AWG ($8.00/ft)

Efficiency: 92% energy retention vs. parallel’s 88% (per NREL tests).

Risks: One failed battery disables the entire chain.

When Parallel Wiring Shines

Scenario: Expanding capacity of a single 48V 300Ah LiFePO4 battery.

How It Works: Connect two 48V batteries in parallel (+ to +, - to -).

Advantages:

Capacity Doubling: Two 48V 300Ah units = 600Ah (28.8kWh).

Redundancy: If one battery fails, the system still operates at 50% capacity.

Drawbacks:

Requires a current-sharing module to prevent imbalance.

Higher upfront cost (two 48V batteries vs. four 12V).

Efficiency Comparison Table

|

Configuration |

Voltage |

Capacity |

Cable Cost |

Efficiency |

Best Use Case |

|

Series |

48V |

200Ah |

$120 |

92% |

Solar Inverters |

|

Parallel |

48V |

400Ah |

$450 |

88% |

Hospital Backup |

Expert Recommendations

DIY Solar Farms: Series-wired 48V LiFePO4 banks cut wiring costs by 60%.

Data Centers: Parallel systems ensure uptime during outages.

Pro Tip: For hybrid setups, use a 48V 4S8P LiFePO4 configuration to balance cost and redundancy.