Step-by-Step Guide: How to Safely Wire 12V LiFePO4 Batteries in Series for 24V/36V Systems

Upgrading your power system to 24V or 36V doesn’t require buying new equipment. By wiring 12V LiFePO4 batteries in series, you can achieve higher voltage for heavy-duty applications like solar inverters or electric vehicles. Here’s a comprehensive guide to do it safely and efficiently.

Why Series Wiring Works for LiFePO4?

Lithium iron phosphate (LiFePO4) batteries excel in series configurations due to their flat discharge curve and minimal voltage sag. Unlike lead-acid batteries, which lose 20-30% capacity when wired in series, LiFePO4 maintains 95%+ efficiency.

Step 1: Battery Selection & Compatibility Check

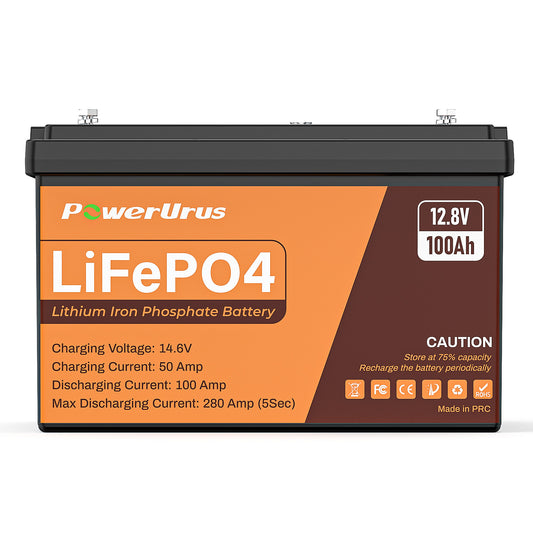

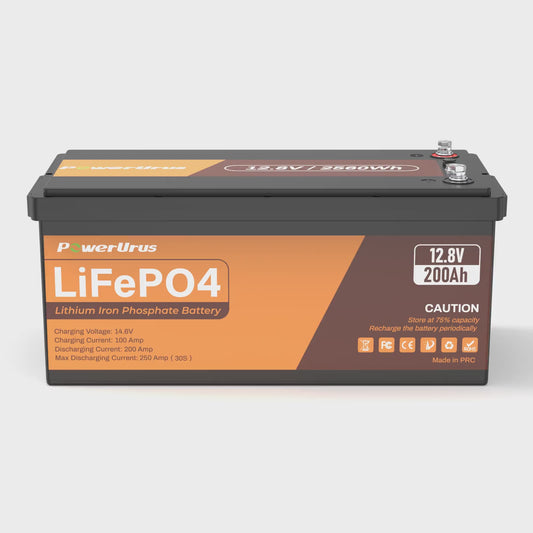

Match Specifications: Use identical 12V LiFePO4 batteries (same capacity, brand, and cycle count). For example, pairing two 12V 200Ah LiFePO4 deep-cycle batteries ensures balanced internal resistance.

Avoid Mixing Old & New: A 2023 study by Battery University found that mismatched cells in series degrade lifespan by 40%.

Tool Tip: Use a multimeter to verify each battery’s voltage (13.2V-13.6V when fully charged).

Step 2: Series Connection Process

Terminal Wiring:

Connect Battery A’s (+) terminal to Battery B’s (-) terminal using 6AWG tinned copper cables (low resistance).

Remaining terminals become your system’s (+) and (-) outputs (24V total).

For 36V: Add a third battery (A+ → B- → C+ → system output).

Safety Gear:

Install 80A ANL fuses between batteries to handle LiFePO4’s 3C discharge rates.

Use heat-shrink tubing on connections to prevent corrosion.

Step 3: Battery Management System (BMS) Integration

A 24V active-balancing BMS is non-negotiable for series setups. It:

Prevents cell overvoltage (critical when charging at 28.8V).

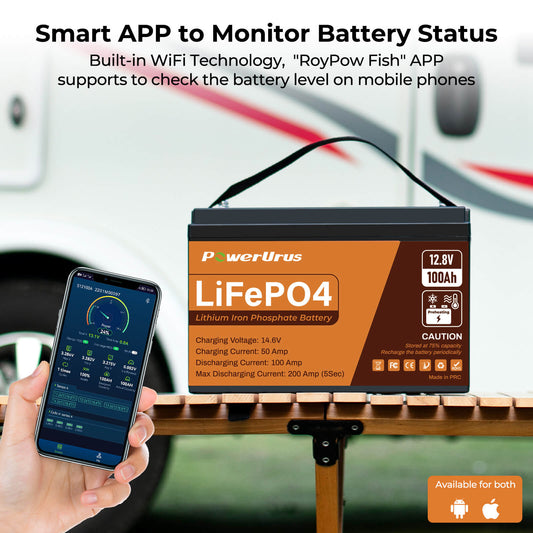

Monitors individual cell temperatures via Bluetooth (e.g., Powerurus Smart BMS).

Pro Tip: Set the BMS’s overcharge cutoff to 3.65V per cell (14.6V per 12V battery).

Step 4: Real-World Testing & Validation

Voltage Check: A 2-battery series should read 25.6V-26.4V at full charge.

Load Test: Run a 500W load for 1 hour. If any battery’s voltage drops >0.5V below others, rebalance using a LiFePO4 balancer.

Case Study: Off-Grid Solar Upgrade

A Montana cabin replaced six 6V lead-acid batteries with three 12V 100Ah LiFePO4 in series (36V system).

Result:

22% lower energy loss during 5kW inverter operation.

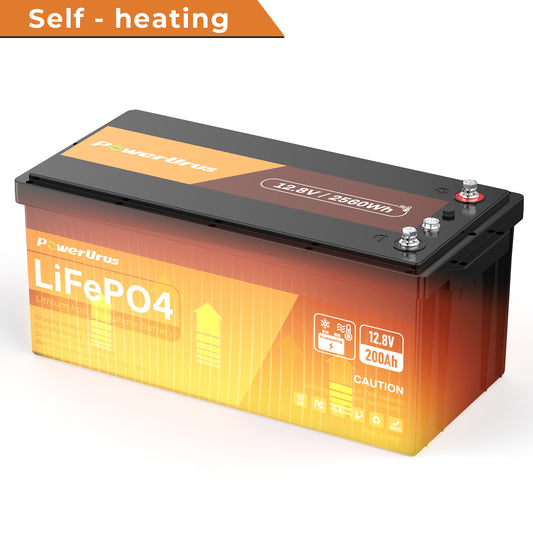

Winter performance: 85% capacity retention at -4°F vs. lead-acid’s 50%.